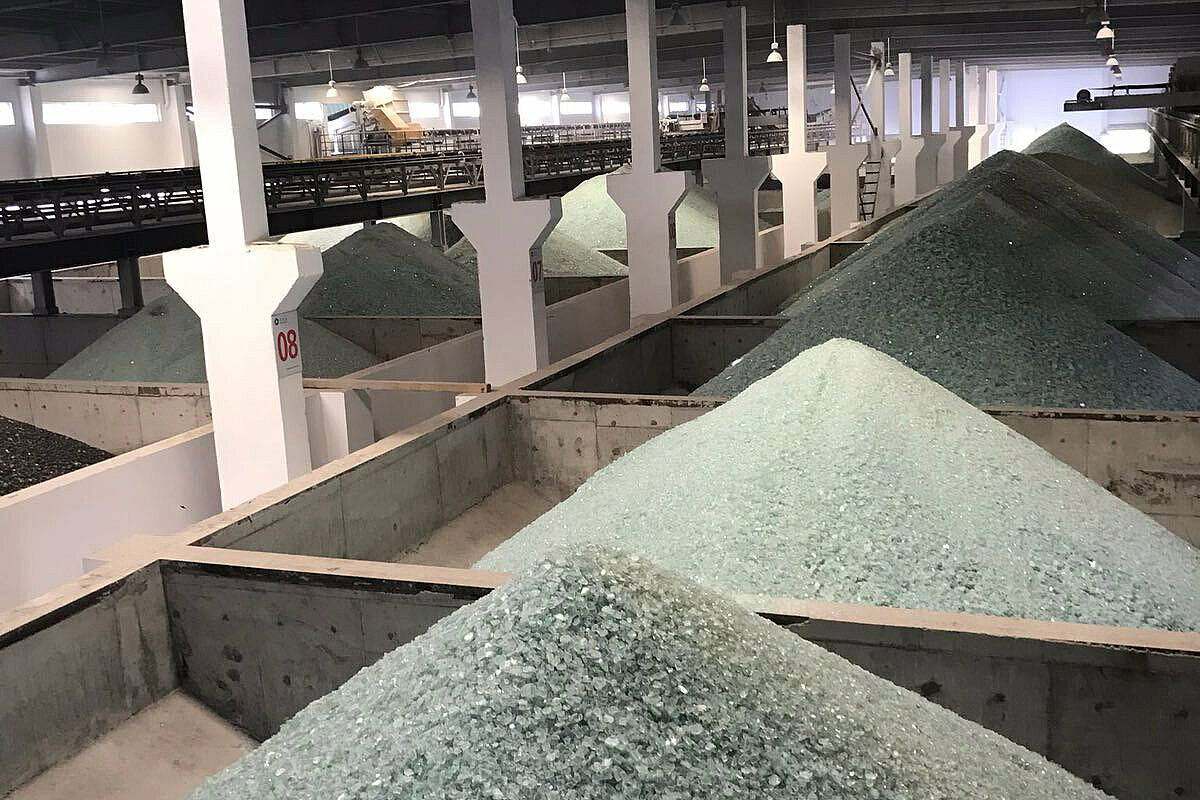

Hollow glass recycling

Processing hollow glass correctly by type using magnetic separation and sensor-based sorting

Magnets, non-ferrous metals separators and sensor-based sorting from a single source.

Glass recycling starts with collecting glass, but glass collections vary significantly from country to country and region to region. Depending on the type of collection, very different processing steps are required to be able to reuse the glass as a secondary raw material.

The biggest proportion of impurities in hollow glass or container glass consists of organic materials, metals, plastics, paper waste, ceramic, stone, porcelain (CSP) and insufficient color purity.

To supply glassworks with recycled raw materials with a pure color and material, recycling and processing plants require reliable sorting systems which meet the high requirements in terms of purity and yield. STEINERT has been a reliable partner when it comes to developing and constructing magnetic and sensor-based sorting systems for many decades.

New glass can now be created from 90% waste glass. For the recycling process to work properly, the following stations are recommended to ensure that the material is clean enough to create new glass packaging from recycled material in the glassworks:

- Our STEINERT overhead suspension magnet typically separates ferromagnetic ferrous parts, such as metal lids, from the input material as part of an extracting operation – optionally as an electromagnet (electric overhead suspension magnet). Some glass recyclers also use electromagnet drums (STEINERT MTE), permanent magnet drums (STEINERT MTP) or permanent magnet magnetic head pulleys (STEINERT BRP) in top-class barium ferrite and/or neodymium quality to separate out ferrous metals.

- The initial screening of the material to separate broken glass from bottles is carried out after coarse ferrous separation.

- The bottles are crushed and, during this process, the bottles turn into fragments and therefore release additional metals and plastics – for example from the bottle tops.

- The iron and non-ferrous metals released in the flow of materials are separated out as part of an additional process step consisting of self-cleaning overhead suspension magnets STEINERT UME or magnetic drums STEINERT BR in combination with an eddy current separator STEINERT EddyC.

- Plastics can also be separated out of the waste flow by the NIR sorting system UniSort PR in order to save on landfill costs.

- After additional screening and initial organic separation, the glass pre-processing is complete and optimally prepared for sensor-based sorting.

- Especially important for MRF operators and glass beneficiation plants, STEINERT’s MSort product range, which has been in use specifically for glass processing for more than 25 years, takes over responsibility for sensor-based sorting. The STEINERT MSort product range is able to remove impurities from the glass and separate glass by color. Beneficiation plant operators also benefit from the MSort product range as it allows them to create cullet to a wide range of consumer specifications.

- Thanks to the free-fall detection, STEINERT’s MSort AX and MSort BE series are particularly suitable for glass processing without technical drying.

- We recommend the MSort AK, MSort AF and the MSort AW series for processing technically dried material, as they are particularly precise and powerful.

- Magnets separate the ferrous materials as a final quality check, i.e. in subsequent cleaning.

MSort sorters are particularly characterized by their process stability – including in the case of fluctuating input power and input quality. We are constantly further developing the sorting systems, while always listening carefully to our customers. The result is that all MSort sorting systems are mechanically optimized to their application. This in turn minimizes the maintenance required for long runtimes.

Thanks to the completely independently developed sorting system, we are able to guarantee to our customers that we keep spare parts in stock for a long time. This applies to both electronic components and updates.

The benefits to you at a glance:

- Sorting from a particle size of 1 mm upwards

- All machines are designed for 24/7 use and need fewer spare parts

- Separation of all impurities from a single source

- Sensor sorting with more than 25 years of experience in glass recycling

- STEINERT magnet technology for ferrous and non-ferrous metal separation

- Separated non-ferrous metals are also marketable

- Separation of impurities and color sorting at the highest level