COLOUR SORTING SYSTEMS

STEINERT’s colour sorting systems allow you to detect valuable residues

Utilise surface colour differences with colour sorting systems from STEINERT

Colour sorting is one of the oldest ways of classifying materials using sensors to separate valuable residues. The detection of colour corresponds closely to the sensory perception achieved by the human eye. Using colour information alone, humans can distinguish between copper and brass or blue and green PET flakes, for example.

The human eye is able to perceive colour information in the visible light spectrum (VIS) of around 400 to 780nm. The VIS spectrum is located precisely between the ultraviolet (UV) and infrared (IR) light spectra, neither of which can be seen by the human eye.

Our detection systems for the VIS spectrum detect colour nuances with high precision in the RGB colour space and are able to detect around 16.8 million colours. We use LED emitters to illuminate the detection area. These emitters deliver numerous benefits in the desired wavelength range and colour spectrum thanks to their long service life, rapid response times, high light intensities and high energy efficiency.

When colour sorting, colour information about the surfaces of the sortable material is determined and used for classification purposes. As with most information obtained using sensors, this mainly relates to secondary features which can be used to characterise useful differences.

The colour information in our UniSort Finealyse can therefore be used in isolation or in combination with NIR or metal detection to sort non-ferrous metals or plastic flakes as of a grain size of 3mm.

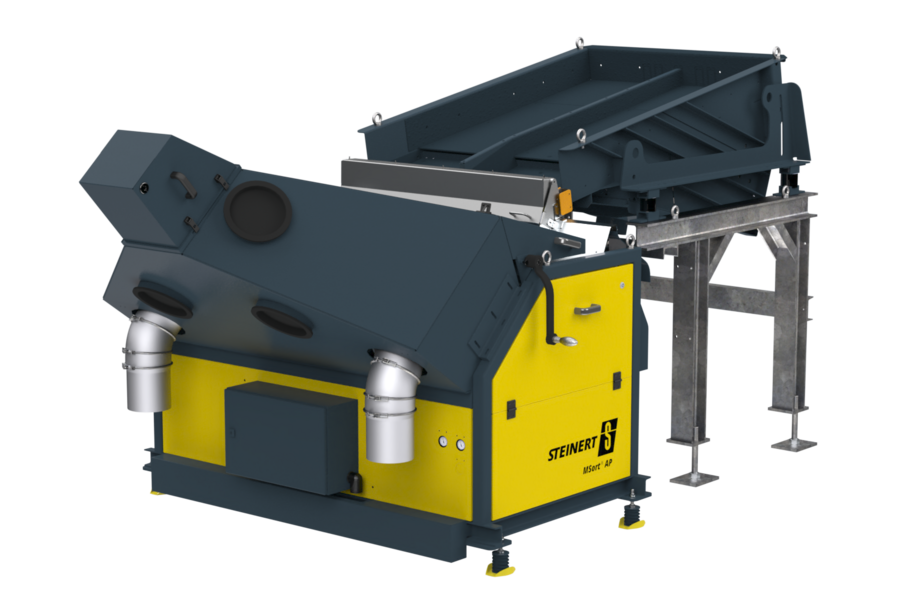

In our STEINERT KSS combination sensor sorting system, colour along with 3D detection can also be complemented by other available detection systems to help with the production of high-quality concentrates for applications such as cables, printed circuit boards or stainless steel.

Your benefits:

- STEINERT KSS | CLI: Non-ferrous metal and printed circuit board sorting (Zorba or Zebra)

- UniSort Finealyse: Copper and heavy metal sorting & sort plastic flakes by colour

- Sorting on the basis of optical features

- The low-cost way to separate non-ferrous metals

- Make effective use of colour information