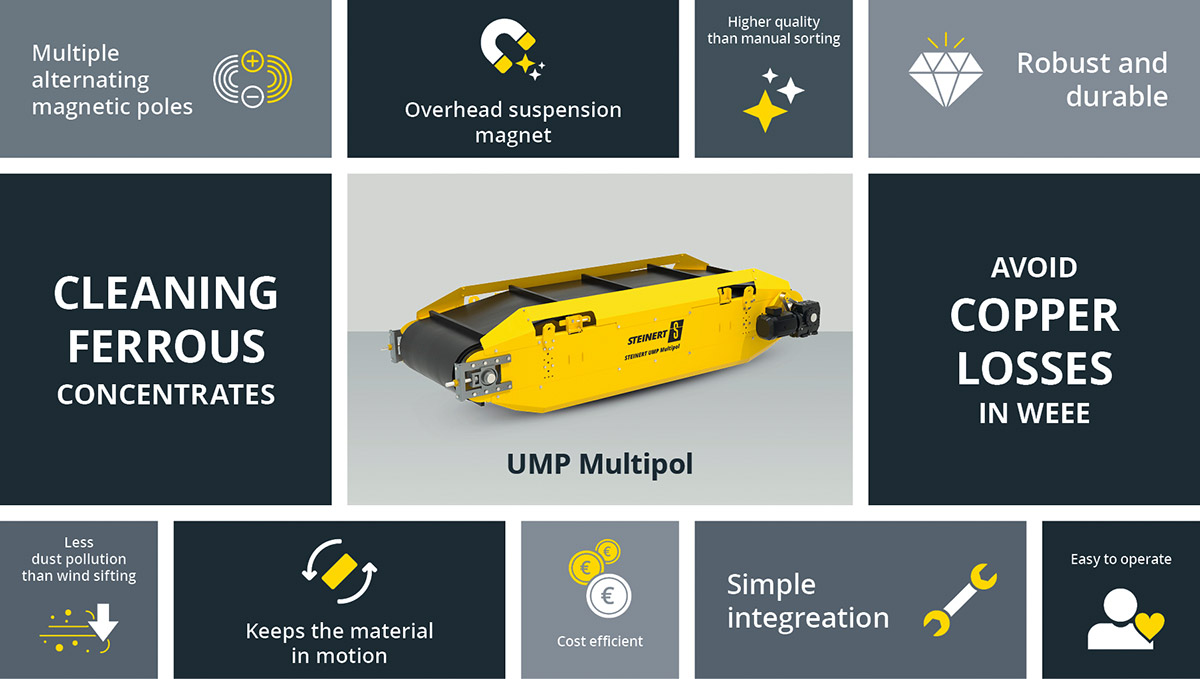

STEINERT UMP Multipol

New quality levels for ferrous concentrates: the STEINERT UMP Multipol

The new UMP Multipol permanent magnet from STEINERT features alternating magnetic poles, enabling it to set new standards in improving the quality of ferrous concentrates and effectively removing impurities.

The STEINERT UMP Multipol provides an advanced solution for enriching and cleaning ferrous concentrates. By changing the magnetic polarity several times, the material is turned over multiple times beneath the conveyor belt, removing non-magnetic impurities effectively. This greatly improves the quality of the ferrous fractions. Furthermore, copper losses in ferrous concentrates can be significantly reduced in Waste Electrical and Electronic Equipment (WEEE) applications.

Efficient technology

The overhead suspension magnet with permanent magnets lifts ferromagnetic pieces of scrap (predominantly iron) out of the material flow against gravity. The innovative process of changing polarity turns the attracted pieces of iron over several times, releasing non-magnetic impurities. At the end of the conveyor belt, the cleaned ferrous material is discharged separately. Using permanent magnets ensures that only minimal levels of energy are required, making the STEINERT UMP Multipol a very cost-effective solution.

Your benefits:

- Clean ferrous concentrates

- Avoid copper losses in WEEE

- Multiple alternating magnetic poles

- Keeps the material in motion

- Sets impurities free

- Less dust pollution than wind sifting

- Simple integreation to existing sorting lines

- Higher quality than manual sorting

Simple integration, maximum efficiency

The STEINERT UMP Multipol can be easily integrated into existing systems and offers a cost-effective alternative to conventional cleaning methods. The permanent magnet is a major further development in the field of magnet technology and provides users with efficiency and quality benefits.

Download

Application expamples