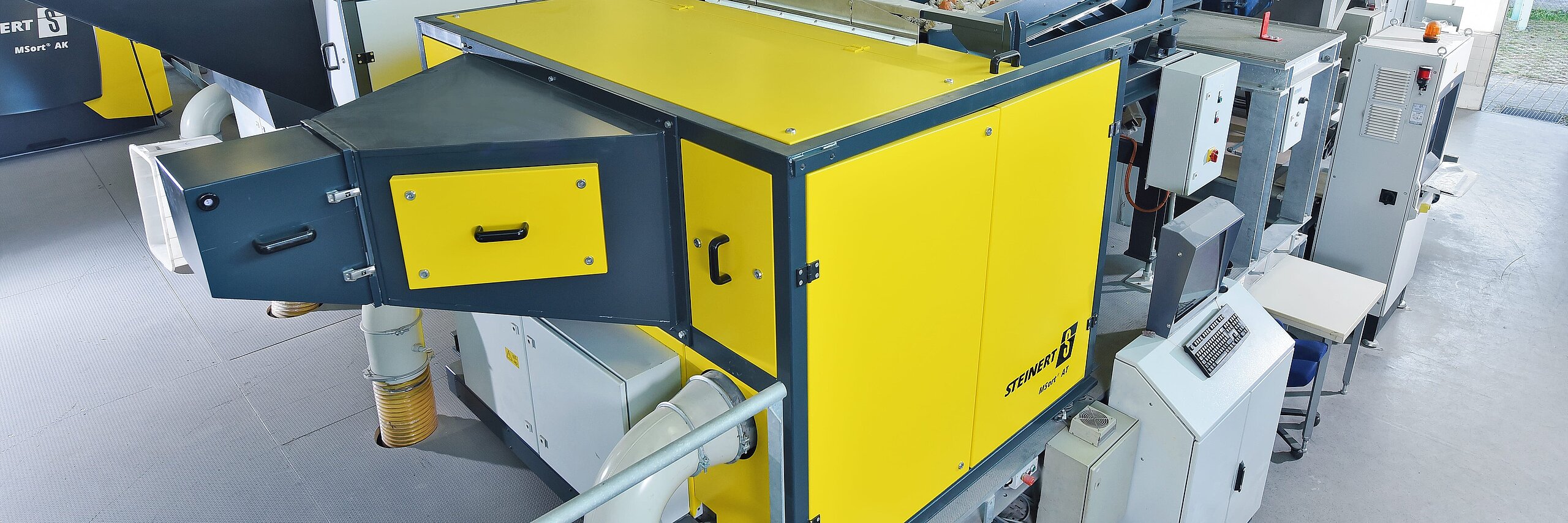

MSort® AT

For maximum precision and flexibility in colour sorting

The colour sorting is controlled in parallel by two cameras and is able to handle damp bulk materials, such as concrete, brick and asphalt, in a coarser fraction range of 20 to 80 mm. There is also a version for particle sizes of 16 to 80 or 8 to 50 mm. In the mining sector, industrial minerals, such as quartz, marble, barite, limestone, calcite and dolomite, are also precisely sorted by colour. The system also enables the production of ultra-pure colour fractions from ores, such as copper oxide, manganese ore and veins of quartz containing precious metals. The structure allows the machine body to be adjusted mechanically so that the valves can be controlled individually and the detection height adjusted to the particle size.

One version of the MSort AT has a working width of 1200 or 1500 mm.

Numerous colour sorting options can be implemented through the use of high-resolution camera technology (in the visible wavelength range) and versatile software. The two cameras are arranged opposite one another for optimum image resolution of the material.

A feeder and vibrating conveyor evenly feed the material to the chute. It is then detected in free fall by a colour camera. Deploying parallel processor technology, the sensor analyses the colour, shape, brightness and transparency using the reflected light method. Materials are evacuated efficiently and precisely using rapid compressed air pulses.

The chute sorting system wins over customers with its durability, need for very little maintenance and free-fall detection function, which enables wet and contaminated material to be sorted without technical drying.

The benefits to you at a glance:

- Particularly effective evacuation with minimal loss of product using two cameras

- Evaluation electronics with protection against overload

- Robust design with solid wear protection

- Chute sorting system

- Fraction size: 20–80 mm

- Requires little maintenance and is easy to service

- Also available: Wear protection, special voltage, division, active cooling (up to +45°C), particle size 16–80 or 8–50, feed distributor, feeder with de-watering

- Flexibility ensured through optional individual control of valves and scope for adjusting height of detection to particle size

- Also available with the 1200 mm working width: Wear protection, special voltage, division, active cooling (up to +45°C)