ALUMINUM SCRAP SORTING

Sustainable value creation with STEINERT technology

Aluminum is everywhere – in cars, construction, packaging, and electronics. Its lightweight, corrosion-resistant properties make it indispensable across industries. But producing primary aluminum is highly energy intensive. Recycling aluminum scrap saves up to 90% of the energy required for primary production and significantly reduces CO2 emissions.

To unlock this potential, precise sorting is key. That’s where STEINERT comes in – empowering recyclers with advanced sorting technologies that enhance purity, maximize recovery, and contribute to a circular economy.

Your benefits:

- Ultra-high aluminium scrap purity of up to 99.8%

- Sorting of heavy metals from aluminium, or differentation of cast and wrought, or separation of magnesium from aluminium with X-ray technology

- Extended sorting of aluminium alloys with laser technology (LIBS)

- Long lifetime of all sorting machine components

- Ferrous and non-ferrous metals, separation with magnet and eddy-current technology

- All magnet and sensor sorting technology from a single supplier

How to sort aluminum scrap

Sorting aluminum scrap is not just good for the planet – it’s good for business. From the collection of used materials to melting and remanufacturing, the process is designed to preserve the value of this versatile metal.

Input material preparation and ZORBA fraction

Aluminum scrap, including profiles, used beverage cans (UBCs), and shredded fractions from end-of-life vehicles and household appliances, but also production or new scrap, enters the recycling stream as part of mixed scrap – or after precleaning referred to as ZORBA.

Pre-treatment and ZORBA processing

This fraction contains aluminum and other non-ferrous metals and must be cleaned and pre-shredded. After this, the scrap sorting process begins.

Separating out iron

Magnetic separation of ferrous metals

Firstly, magnets are often used to separate free iron pieces and compounds out of the material flow. This is essential to prevent contamination in subsequent processing steps and to recover valuable ferrous metals.

STEINERT magnetic solutions

Magnets such as STEINERT BR magnetic head pulleys and STEINERT UME overhead suspension magnets are often used for this purpose. They ensure efficient and continuous removal of iron components from the scrap stream.

Non-ferrous separation

Recovering non-ferrous metals and aluminum

After removing ferrous using magnetic separation, the next step is the extraction of non-ferrous metals. For this process step our eddy-current separator STEINERT EddyC has become a global standard. The so called non-ferrous metal separator recovers nf-metals while cleaning the metal fraction from undesired materials like plastics, wood or glass. The generated ZORBA predominantely consists of aluminum, but also contains heavy metals like copper, brass or zinc.

Sensor-based sorting in an aluminum recycling process

ZORBA fraction purification

This mixture of light and heavy metals (separated by grain size) is now separated using X-ray technology (STEINERT XSS T EVO 5.0) into aluminum and the mixed fraction of copper, brass, zinc, etc. This achieves a maximum yield and purity of aluminum and the material can be marketed in a defined quality.

Application for profiles and light aluminum scrap

For fractions of profiles and light aluminum scrap, wet mechanical separation of free heavy metals and high-alloy aluminum components (such as cast parts) is often not economically viable.

Dry sorting by atomic density

In such cases, dry mechanical sorting by atomic density provides a reliable alternative or flexible addition to sink/float separation to meet changing quality requirements. The above-mentioned grain-size-separated fractions are then processed using the STEINERT XSS T EVO 5.0.

High-purity aluminum output

This system effectively separates aluminum scrap from a mixed fraction of copper, brass, zinc, and other free heavy metal pieces. It enables the separation of high-alloy aluminum and free heavy metals, achieving aluminum scrap purities of more than 99.8%.

Cast / wrought separation

The separation of cast and wrought aluminum using XRT-technology is essential to preserve material quality and value. Cast aluminum typically contains high levels of alloying elements such as silicon—often exceeding 15 %—while wrought alloys have significantly lower silicon content, usually between 0.3 % and 5 %. When both types are melted together, the silicon-rich cast aluminum contaminates the wrought fraction, making it unsuitable for high-quality applications. Since silicon cannot be efficiently removed in metallurgical processes, dilution with primary aluminum remains the only option—an expensive and resource-intensive approach.

Maintaining a clean and clearly defined wrought fraction is therefore crucial. It not only prevents downgrading of valuable material but also forms the foundation for subsequent alloy-specific separation steps, ensuring the highest possible purity and quality in aluminum recycling processes.

Modular process for specific aluminum grades

The two-step approach with eddy current separation and sorting by atomic density not only maximizes aluminum yield and purity but also enables recyclers to market the material in well-defined qualities – such as Al 224, Taint Tabor (mainly clean sheet goods), or high-value premium grades. Our systems are modular and scalable – tailored to your input streams and desired product purity.

Enriching Free Magnesium in NF Metal Streams

In mixed non-ferrous metal streams, aluminum is often accompanied by small amounts of the light metal magnesium. Since magnesium has an even lower density than aluminum, advanced sorting systems using X-ray transmission (XRT) can identify and separate it as a distinct material class.

By analyzing material density and atomic composition, XRT technology enables the targeted enrichment or removal of free magnesium, depending on process requirements. This precise detection ensures that valuable light metals are recovered efficiently, while minimizing contamination within aluminum fractions and enhancing the overall purity and value of the recycled output.

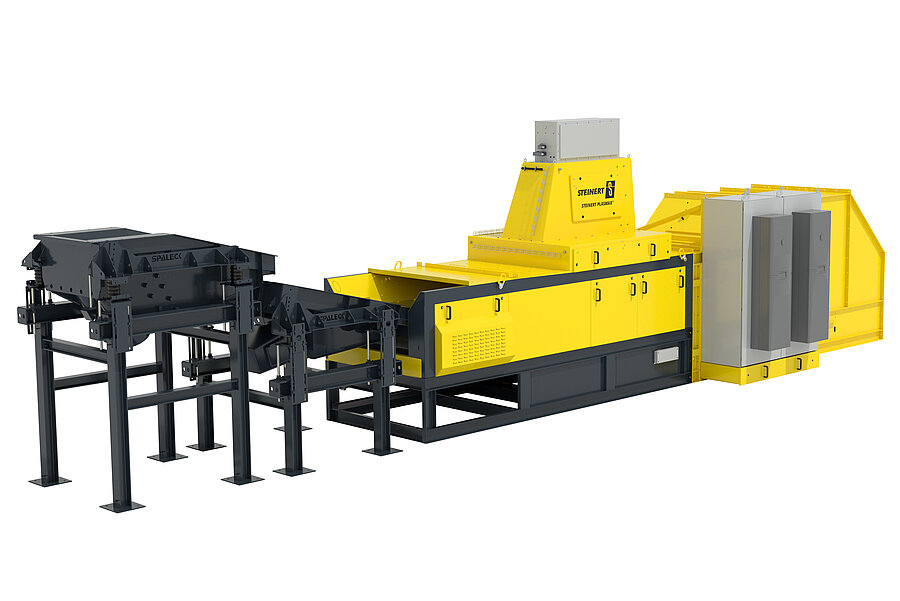

STEINERT PLASMAX | LIBS

Game-changer for aluminum alloy sorting

Market demand for specific alloy grades

Alloy sorting is the next frontier in aluminium scrap recycling. Some customers, especially in the automotive and aerospace sectors, demand specific alloy grades. Sorting similar-looking aluminium alloys by hand is impossible.

High-precision alloy separation with STEINERT PLASMAX | LIBS

With STEINERT PLASMAX | LIBS, we make high-precision separation of aluminium alloys not only possible, but efficient. Alloy series such as 5xxx, 6xxx or 7xxx as well as more specific alloys such as 6063 can be sorted by exact chemical composition – enabling closed-loop recycling and maximum material value.

Technical features and sorting performance

Using laser-induced breakdown spectroscopy (LIBS), this innovative system identifies and sorts alloys based on their exact chemical composition. Whether it’s distinguishing between 5xxx and 6xxx series, or removing unwanted magnesium, PLASMAX offers:

- 3 products in 1 sorting run

- Sorting rates up to 11 t/h with unmatched precision

- Clean alloy fractions ideal for closed-loop recycling

- Reduction of downcycling and material loss

Melting and remanufacturing

High-quality feedstock for furnaces

Once sorting in an aluminium recycling plant has ensured high-purity aluminium fractions, the final stage is melting and remanufacturing. Here, the benefits of STEINERT technology fully unfold.

Benefits for aluminium producers

Because the sorted aluminium meets tight quality specifications, aluminium producers can feed their furnaces with confidence—without additional manual sorting or costly corrective steps.

Reintegration into industrial production

These materials are then turned into semi-finished products like slabs, ingots, or extruded profiles and re-enter the production cycle across various industries – from construction to transportation to packaging.

Thanks to STEINERT’s upstream sorting technologies, the feedstock is exceptionally clean, reducing furnace slag, stabilizing process conditions, and increasing throughput. This translates into significant energy savings, minimized material loss, and improved overall plant efficiency and profitability.

Conclusion

The future of aluminium scrap sorting lies in smart solutions. STEINERT technologies support recyclers worldwide in unlocking the full value of aluminium scrap – for profit, for quality, and for the planet.