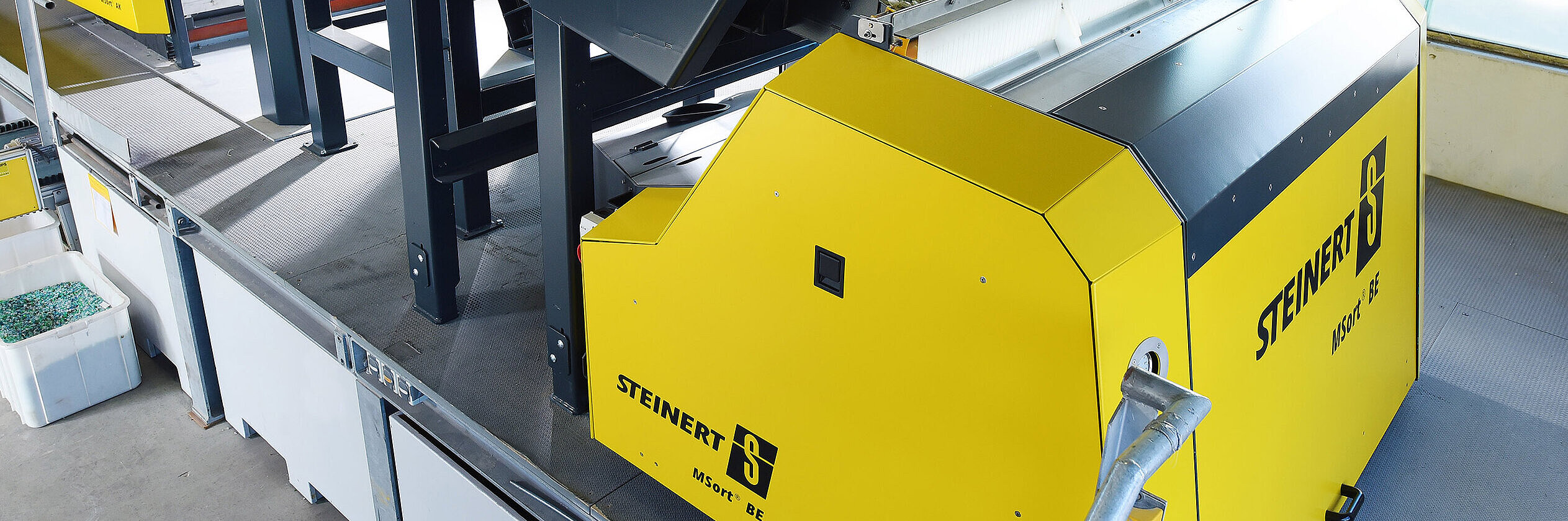

MSort® BE

Cost-efficient colour sorting of wet and dry glass

The MSort BE sorting system in a particle range of 8–60 mm is particularly cost-effective and is particularly suited to sorting glass by colour and separating ceramic, stone and porcelain (CSP for short) from glass up to max. 12 t/h.

The material is added via a feeder. The material spreads out and moves evenly over a vibrating conveyor until it drops to the chute. The colour camera instantly detects the material when it is in free fall.

Thanks to the free-fall detection, the MSort BE sorting system is ideally suited for sorting wet glass. It prevents incorrect removals caused by dirty glass chutes and prevents misses caused by wet glass being stuck to the glass chute.

The state-of-the-art parallel processor technology uses shape and colour as the criteria for image evaluation. The sensor detects the true colours and colour intensity in detail. It also detects the transparency of the glass fragments using different forms of exposure within the range of visible light.

The colour camera also detects the particle size or shape (length and width ratio) in the visible range. The detection process can be used for statistical purposes and quality assurance at the same time as the sorting task.

Once detection is complete, the product flows can be separated out and then discharged using a compressed air pulse.

There is also the option to add inductive detection to remove ferrous and non-ferrous metals of 0.8 mm and above with the highest levels of sensitivity.

The benefits to you at a glance:

- Glass sorting

- Cost-efficient design

- Chute sorting system

- Fraction size: 8 - 60 mm

- Accurate position detection and discharge

- Also available: all-metal detection from 0.8 mm and above