ALUMINIUM RECYCLING

Effective recovery and quality improvement for aluminium scrap

Cost-effective sorting of various aluminium fractions from recycling processes for use in the production of secondary aluminium

Aluminium can be 100% recycled. Secondary aluminium from recycled material, also known as green aluminium, cuts energy use in production by up to 90% compared with virgin material.

(To find out how aluminum recycling can save so much energy, read here.)

If recovered aluminium (recycled aluminium) is being used to produce new products, aluminium manufacturers need their secondary raw materials to display consistently high levels of purity. This challenge can often be met through sorting. Demand for aluminium for use as a lightweight, high-performance material is growing all the time. Aluminium is increasingly taking the place of conventional materials, such as steel, to save weight and therefore energy, especially in automotive engineering. This makes the recovery of this metal of ever greater interest as a value-creating process.

Your benefits:

- Purity of sorted products, high selectivity and detection

- Ferrous and non-ferrous metals, separation with magnet and eddy-current technology

- Alloy detection, detection of heavy and light elements with x-ray technology

- Extended sorting of aluminium alloys, discrimination between cast and wrought alloy with laser technology (LIBS)

- Long lifetime of all sorting machine components

- All magnet and sensor sorting technology from a single supplier

Not all aluminium is the same

Aluminium scrap has a wide range of material compositions and fractions. It comes from a wide variety of built-in products and components. As alloy components, silicon, manganese, copper, zinc and magnesium increase the strength of the aluminium and determine the primary and secondary uses of plates, rods and tubes, etc. The composition of alloys also determines the ‘castability’ - which is an advantage for complex components such as alternators. The best castability is that of AlSi compounds (4000 class). In some cases, these also contain elements of Mg and Cu to increase strength.

Profiles, cans, plates etc. in wrought aluminium are normally low in alloy components and can be used in almost all secondary processes. In the mechanical recovery of wrought aluminium, the main task is separation of heavy metal components, which are exposed during shredding, e.g. by hammer mill or rotary shear.

Separating out iron

Firstly, magnets often separate the iron content out of the material flow. Magnets such as STEINERT BR and STEINERT UME overhead suspension magnets are often used for this purpose.

Dry-mechanical sorting using XRT (x-ray transmission)

For fractions of profiles, light aluminium scrap, wet mechanical separation of the free heavy metals and higher-alloy Al components (cast components) is generally not worthwhile in economic terms. In this case, our dry mechanical sorting by atomic density using the STEINERT XSS T EVO 5.0 x-ray sorting system is a reliable alternative or addition to sink/float separation for sorting higher-alloy aluminium and free heavy metals, thereby enabling aluminium purity levels of >99.5% to be obtained.

Recovering non-ferrous metals and aluminium

In the case of scrap aluminium from the auto shredder, this is often higher-alloyed material containing 4 to 12% silicon plus primarily copper and zinc. The greater the Si content, the less ductile the component, which will break up during shredding into many smaller pieces. We use this property in our solution and sort the non-ferrous product flow of the shredder in grain sizes e.g. 10 - 30 mm, 30 - 70 mm and 70 - 150 mm using a non-ferrous metal separator (STEINERT EddyC) into the “ZORBA fraction”.

Recycling aluminium and sorting heavy metals

This mixture of light and heavy metals (separated by grain size) is now separated using x-ray technology (STEINERT XSS T EVO 5.0) into aluminium and the mixed fraction of copper, brass, zinc, etc. This achieves a maximum yield and purity of aluminium and the material can be marketed in a defined quality, e.g. Al 224, or coarse grain sizes as Taint Tabor (mainly clean sheet goods) as well as premium fractions. Against a background of increasingly difficult export conditions and growing demand for qualities which can replace and supplement virgin material wherever possible, it is important to generate consistently high purities across all products.

Using LIBS technology to separate alloys

High-quality aluminium from product cycles and material recovery facilities with low alloy components, filler metals or light element content such as magnesium can be upgraded into very pure products using laser-induced breakdown spectroscopy (LIBS). Our STEINERT LSS | LIBS sorts the objects by chemical composition with high isolation to meet your requirements by means of material separation and product discharge within the system. This solution gives secondary smelters the opportunity to use more secondary material and charge the smelt on the basis of alloys. The need to sort within alloy classes, e.g. between the 5000 and 6000 classes of wrought alloy commonly used in automotive engineering, places particularly stringent demands on the depth of analysis of detection. Here the main difference is in the magnesium and silicon content in the alloys, which determine the material properties relevant to the components. These days, the quantitative determination needed for these alloy components can be performed with the LIBS method and is already being used in industry. In principle, this can also be used to quantitatively determine all the alloy components of significance for the aluminium alloy groups 1000 to 7000.

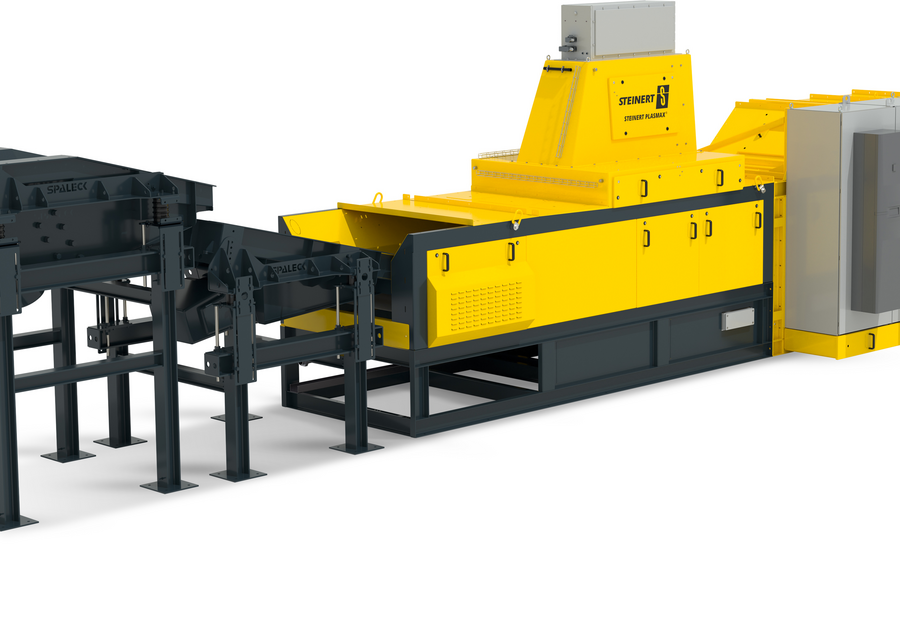

Aluminium Recycling with STEINERT PLASMAX | LIBS

The STEINERT PLASMAX LIBS sorting system is a new addition to our machinery, setting new standards for sorting aluminium alloys. Its multi-spot analysis ensures precise separation of aluminium grades 5xxx and 6xxx into furnace-ready qualities. With efficiency and a capacity of up to 6 t/h, it’s the ideal solution for today’s recycling challenges.

A particular feature is the detection and separation of painted aluminium plates before smelting in order to remove traces of titanium dioxide or even lead and cadmium from the paint and coatings. Here our STEINERT KSS | NR CL analyses the material surface by colour, laser or infrared detection. The relevant items are separated off for separate treatment.