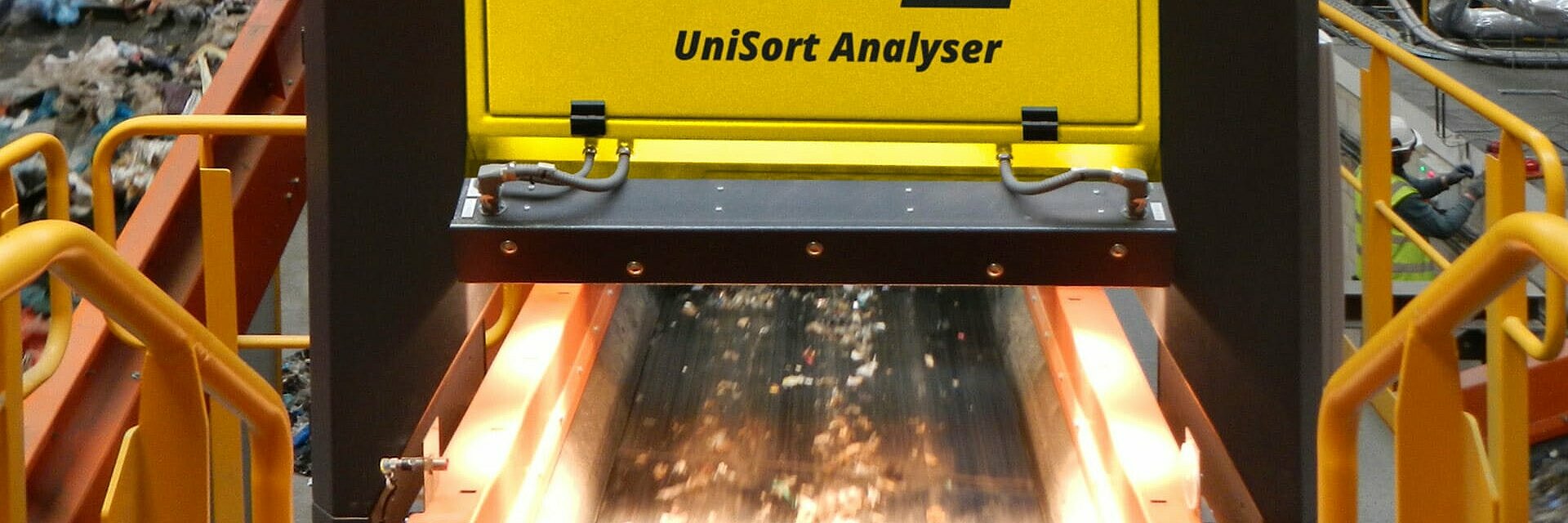

UniSort Analyser®

Contactless online quality control

Our UniSort Analyser can record the currently produced quality online as a final quality control and make it available for secure tracking.

The UniSort Analyser from STEINERT enables contactless quality monitoring of individual product streams in real time. Detection is based on our HSI technology developed in-house using a very high optical and spectral resolution.

In practice even small grain sizes, such as finished substitute fuels, can be effectively recorded and evaluated for analysis.

Parameters such as material composition, chlorine content or the proportion of water are usually recorded. The data provided by the system can be delivered to a parent controller via network connection. This can then evaluate it with regard to the production process and archive it for tracking the operating states of the entire system.

In addition to quality monitoring and control of the upstream machine technology, the UniSort Analyser can also be used for container management. Should the quality currently being produced exceed certain preset thresholds, for example, a second container can be delivered by travelling belt so as not to endanger the actual target quality in the main container. The main container can be put back into position once current production returns to the desired level.

Your benefits:

- Online quality control

- Proactive system control

- Online acquisition of operating data

- Increase in plastic ratios

- A basis for billing costs