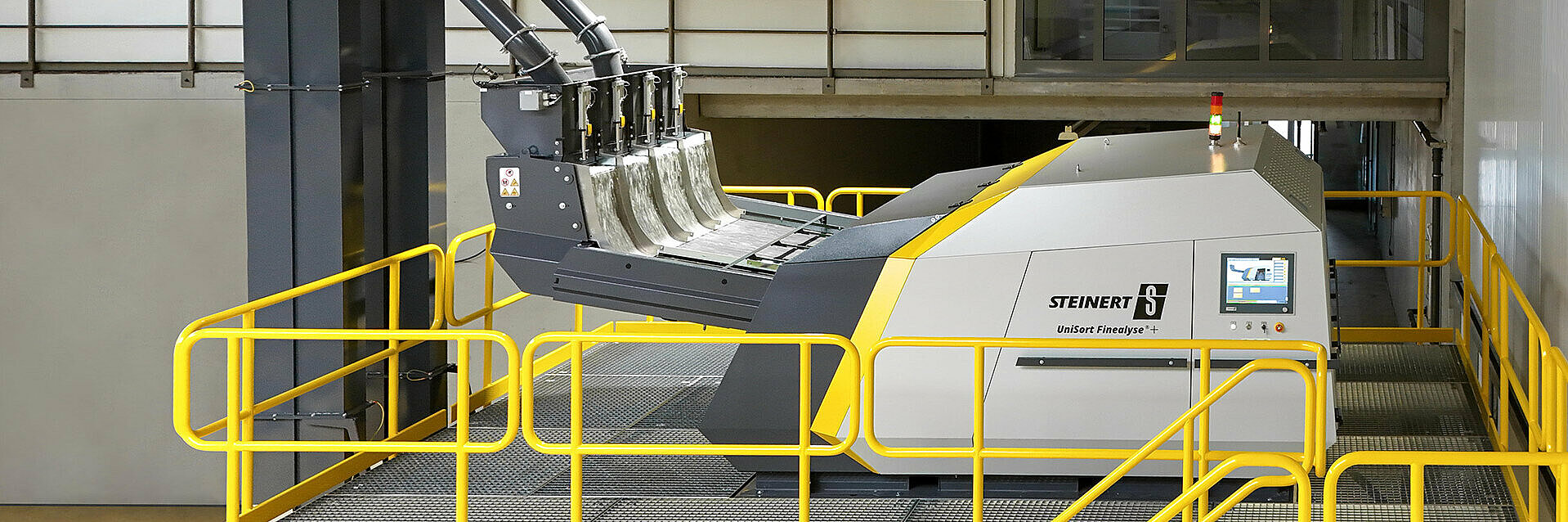

UniSort Finealyse®+

UniSort Finealyse+ is a higher-performing version of its established UniSort Finealyse sensor sorting system.

This new machine was developed especially for the challenges experienced when processing plastic flakes and granulates as well as when sorting metal granulates with grain sizes ranging from 2 to 30 mm.

The diverse potential uses for this product range from sorting plastic flakes to metal applications. UniSort Finealyse+ reliably removes incorrect colours and unwanted plastics from plastic flakes. It is also well suited to colour sorting of non-ferrous metals in addition to removing unwanted plastics from e-scrap. This all results in high flexibility and product purity with minimal material losses.

The sorting unit is available with a high resolution NIR (near-infrared) camera, with a highly selective colour detection unit or with NIR and colour sensor combination with sensor fusion technology. The sensor combination including a colour camera, allows additional characteristic properties that can be identified and mapped at the same point, ensuring even more stable detection.

The material is passed through a feed and dispensing device and lands on the integrated conveyor belt. The feed material is accelerated by a high-speed belt and pressed onto the belt using the active object control (AOC) system developed by us at STEINERT – and is held in a stable position even after leaving the belt. This relatively elaborate but effective stabilisation helps to steady even the smallest objects on the belt in a controlled manner and keep them in the calculated position on the parabolic trajectory after leaving the belt.

Whilst the sortable material flows through the detection area, the corresponding sensor detects the type or colour as necessary and the position on the conveyor belt. The controller then activates the correct nozzles at precisely the right time and position. The nozzle bar is arranged above the material flow and shoots from top to bottom. Detected foreign particles are then extracted exactly and with low material loss by a targeted blast of compressed air. The sorted fractions can be transported to the next processing stage on material discharge conveyors.

For the best possible sorting at all times, UniSort Finealyse + also provides an automatic white balance for calibration purposes and a split variant for simultaneously running several sorting processes on one machine. The split function allows several material flows to be sorted at the same time or for the sorted product to be subsequently cleaned in parallel on one machine.

Your benefits:

- Low over-sorting

- Conveyor belt system (no slide)

- Fraction size: 2–30 mm

- Programmable for different sorting criteria

- Accurate detection of position and discharge

- Modular structure for sorting plastics and metal