Maximum Aluminium Purity for the Circular Economy

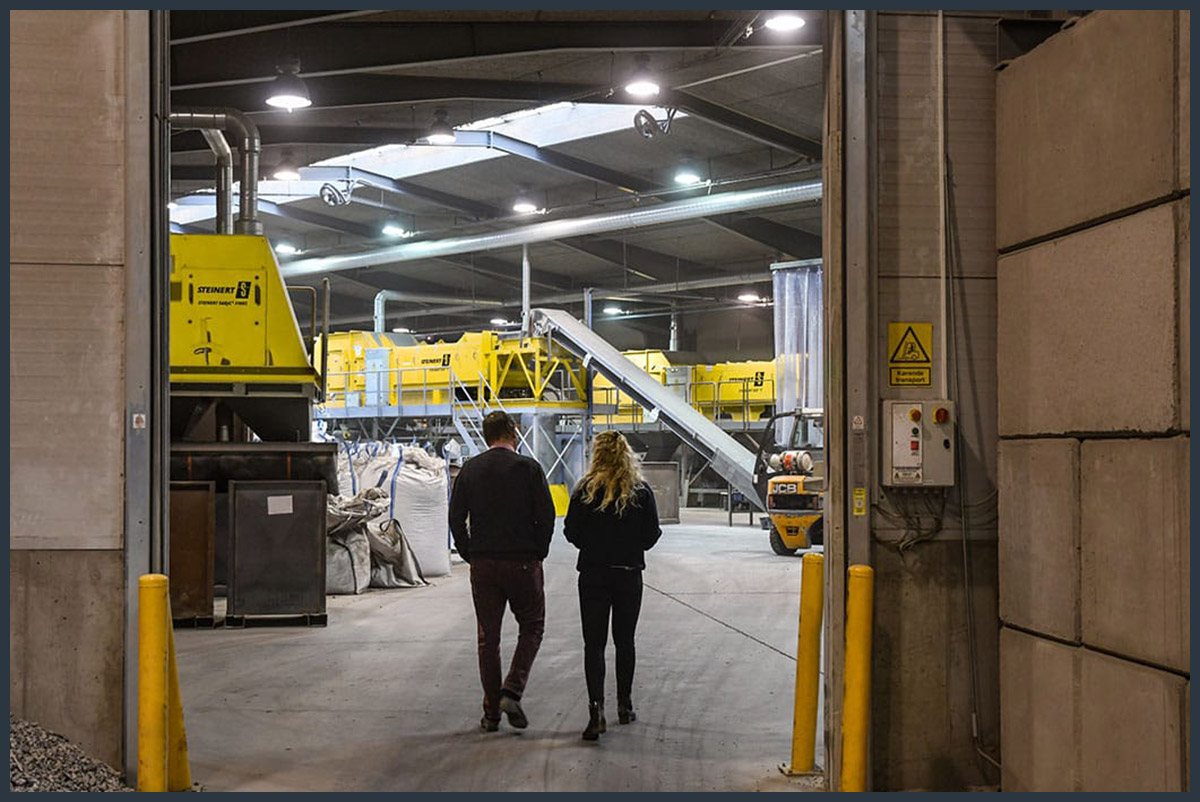

In order to conserve resources, we need to reuse raw materials as often as we can. This requires recycling materials flows that have as high and as consistent a quality as possible. It is only with efficient sorting technology that resources can be continually recycled. The STEINERT XSS T uses X-ray transmission (or XRT for short) to reliably achieve extremely high purity levels when recycling aluminium. EVO 5.0 is the latest evolutionary stage. Several customers explain here why they are so impressed with the equipment.

More and more companies are looking to save resources and expand their use of secondary raw materials. This approach can deliver a significantly lower carbon footprint and improve the security of supply.

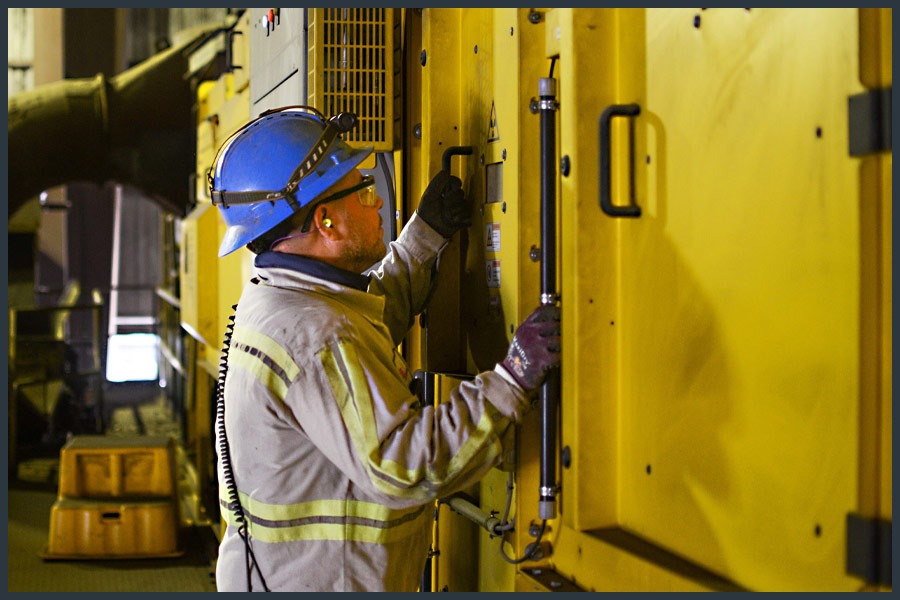

STEINERT has long been an important partner to metal recycling firms. Its technology for dry density separation has been successfully established for a number of years now. The systems are based on x-ray transmission and are designed especially for separating heavy and light metals in metal processing. The STEINERT XSS T produces extremely pure aluminium. The sorting equipment's detection rates are so precise that it can achieve an aluminium purity of 99.8%.

STEINERT XSS T EVO 5.0

Sensor sorting

Density sorting with the STEINERT XSS T EVO 5.0 - via x-ray transmission under the dual-energy principle