LIBS sorting systems

Maximising the value of aluminium: LIBS solutions for segregated alloys

In order to meet the growing demand for aluminium products, the industry needs solutions to upgrade mixed aluminium packages to segregated series/alloys. LIBS technology will be the primary enabler of this upgrade, allowing more recovered aluminium to reach its highest and best use, maximising its value.

Lighting the path: LIBS unravels elemental compositions

LIBS stands for Laser Induced Breakdown Spectroscopy, a technology that analyses material according to its elemental composition. A high-energy laser beam vaporises matter on the surface, creating a plasma which then breaks down with characteristic light emissions. The spectral analysis of these light emissions allows the elemental composition to be determined. These determinations allow aluminium series/alloys to be separated from each other.

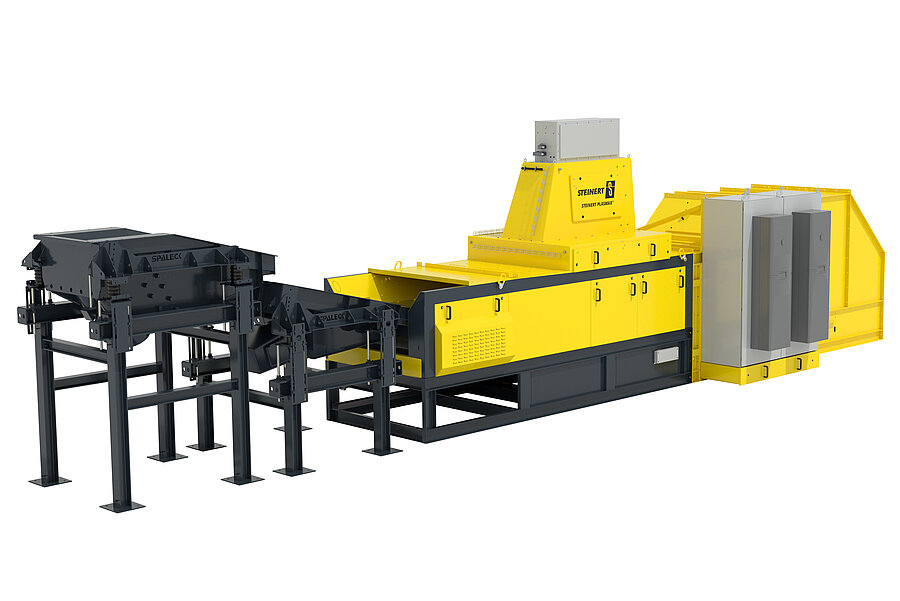

LIBS technology is most often used in conjunction with X-ray transmission (XRT) technology, such as the STEINERT XSS T EVO 5.0 or STEINERT KSS XT | CLI. Specifically for post-consumer streams, XRT is used to remove heavy metals, compound materials and cast aluminium, leaving clean wrought aluminium.

How metal recyclers benefit from using LIBS technology

Rather than creating a mixed Zorba or Twitch package, processors can cost- effectively extract valuable wrought aluminium series/alloys from their streams.