STEINERT MTE

Durable electromagnetic drum separator with high power density – the STEINERT MTE

Magnetic drum separator with ANOFOL electromagnets in a proven design

Electromagnetic drum separators are available in both disc and transverse pole versions. In the STEINERT MTE Q transverse pole version there are several magnetic poles aligned parallel to the axis. The first pole generates a particularly extensive, strong field in the material feed direction to effectively collect the incoming, shredded scrap. Further poles retain the material on the drum shell. The magnetic field pattern is constant over the width of the drum and alters in the direction of rotation. The scrap is removed and guided to the discharge by reversal of the polarity. Its excavating operation and optimised magnet design result in the STEINERT MTE Q recovering very high quality iron. This classic shredder drum contains an iron core with specially shaped poles and high-performance ANOFOL coils made of anodised aluminium strip.

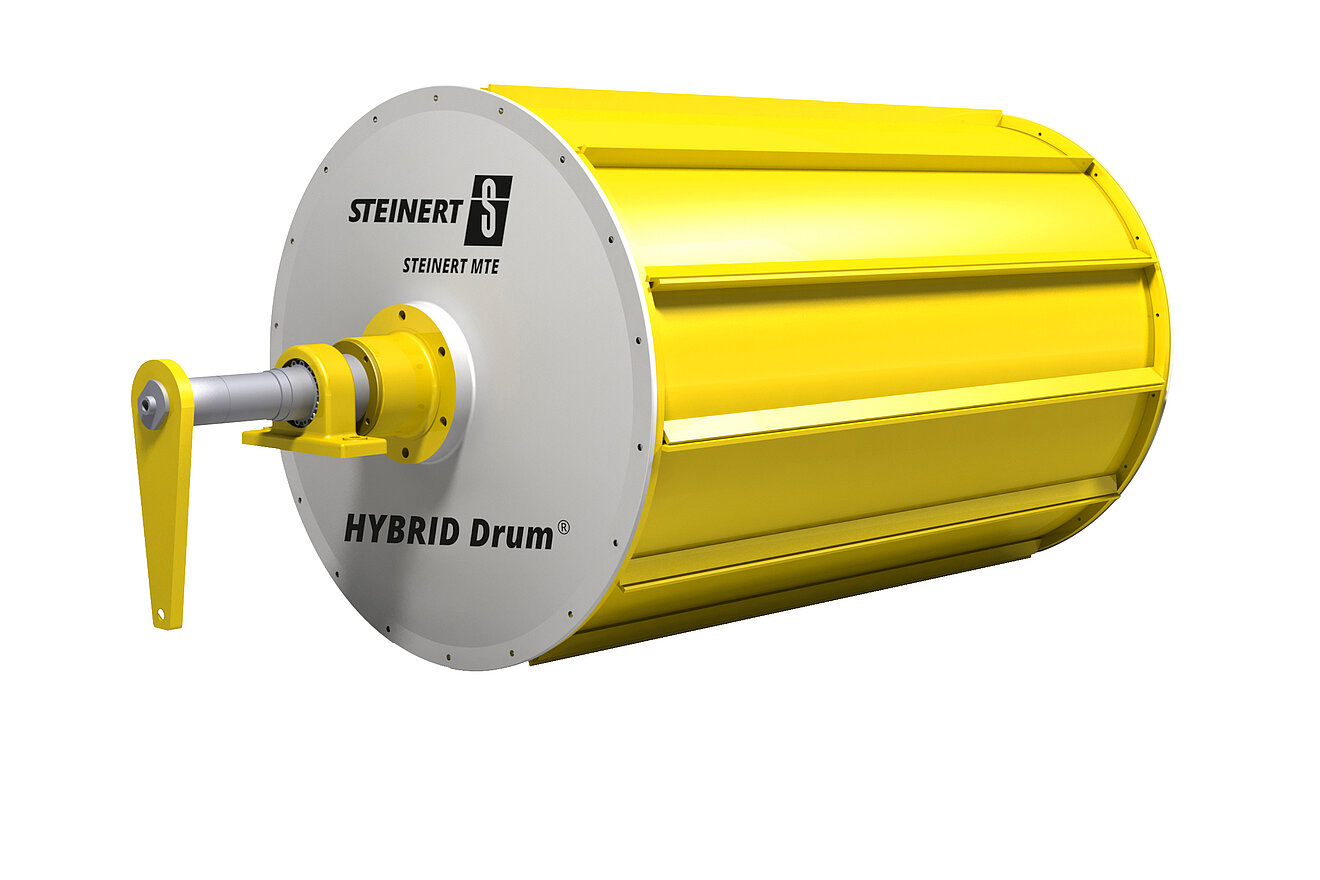

We were able to further increase metal recovery productivity by introducing the HYBRID Drum. The combination of even stronger electromagnetic ANOFOL coils and permanent magnets increases performance by around 30%.

In addition to the transverse pole version, on request we supply the electromagnetic radial pole equipment as a special version. The STEINERT MTE S electromagnetic drum with radial pole removes ferrous particles from bulk material in traversing arrangement. The magnetic field is generated by a radial pole system consisting of semi-circular cast steel bodies with intermediate excitation coils made of ANOFOL anodised aluminium strip. These compact, very powerful coils generate such large retention forces that we have accordingly adjusted the thickness and material of the drum shell to these high demands in terms of wear and deformation.

The magnetic application point for all systems can be exactly selected via the adjustability of the magnet system; this allows easy optimisation of the respective product. We supply our STEINERT MTE in working widths from 800 mm to 3,400 mm and in diameters ranging from 800 mm to 1,800 mm to correspond with a wide variation in throughputs and grain sizes.

Your benefits:

- MTE = electromagnetic drum

- Extensive magnetic field for extraction operation

- Also available as HYBRID Drum for particularly high performance

- Working widths: 800 – 3,400 mm

- Diameter: 800 – 1,800 mm