Intelligent low-grade stockpile treatment with ore sorting

We have the solutions for turning low-grade stockpiles into income sources: by minimising disposal costs for the heaps and recovering valuable residues

Spoil heaps are usually unavoidable by-products of the effort to reach richer ore layers. Typically, heaps are left to accumulate until the available space runs out or until regulations require the operator to take measures to reduce them. Unfortunately, the material cannot be utilised economically with conventional processes, because the mineral content is far below the acceptable tolerances. Rather, the heaps must be removed with diggers and loaders and disposed of elsewhere. This results in considerable costs for the removal, transport and landfill.

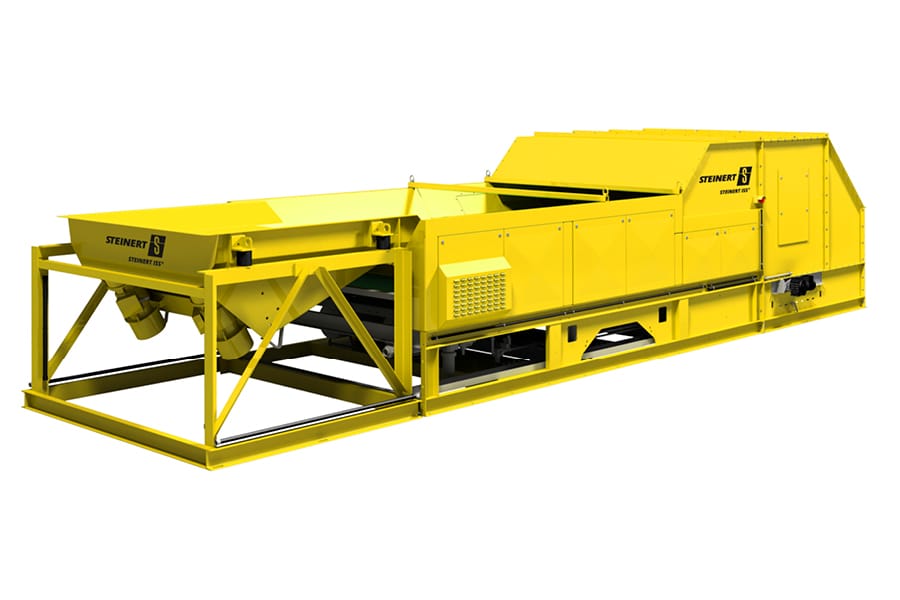

By using effective ore sorting equipment, however, such as our STEINERT XSS T EVO 5.0, which uses 'dual energy' x-ray transmission (XRT) to detect differences in atomic densities, this process can be optimised. The system detects valuable ore with its x-ray sensor and uses compressed air to remove it from the product stream. This greatly reduces the proportion of low-value waste rock (gangue). A concentrate of high-quality ore can be further enriched during processing.

Frequently the mineral content is so high that the product obtained is of the same quality as the crude material obtained directly from the mine. A welcome side-effect is that the waste rock usually has such low mineral content that it can be sold as gravel. You can thus convert material that was written off into an additional income stream while reducing disposal costs.

We can provide special sensors and machines for different applications and tasks. Depending on the precise task, we can offer you XRT (x-ray transmission), XRF (x-ray fluorescence), laser, near-infrared, optical or inductance detection. Additionally, STEINERT's semi-mobile series enables you to operate your ore sorting plant independently of location. You can of course use them as stand-alone units, or alternatively, combine them with others to form a robust, large-scale system. They are perfectly suited to landfill reclamation, the removal or restructuring of spoil heaps and many other special tasks.

- Market waste rock as gravel

- Recover valuable metals

- Reduce spoil heaps

- Utilise written-off ores

- Capture additional income streams

Application areas

The perfect solution for your requirements

STEINERT WDS

For recovering magnetite and ferrosilicon from heavy solutions or iron ore at grain sizes between 1 µm and 3 mm

Product link

STEINERT KSS® | NR CLI

sorting system combines modular multi-sensor systems including the NIR range

Product link